Industrial Automation Projects Gallery

Highlighted Projects

Animated Figures in Theme Parks

Animated figures for theme parks in the USA and China are designed with advanced technology from Third Coast Automation. Controls include Rockwell PLC, Kinetix servos, Elmo servos, FT View SE HMI, Harmonic Drive actuators, and a proprietary show animation profile system.

Metal Stamping Press Feed Line Guarding Integration

Integrated new fence guard door switches by Third Coast Automation into an existing metal feed line to an 800 ton servo press.

Glucose Monitoring Meter - Assembly System

Designed and programmed the PLC-based control system with 2 PLCs, 13 vision PCs, 7 Adept Robots, multiple flex feeders, 2 tray handlers, and a full meter programming system, including final quality control checks.

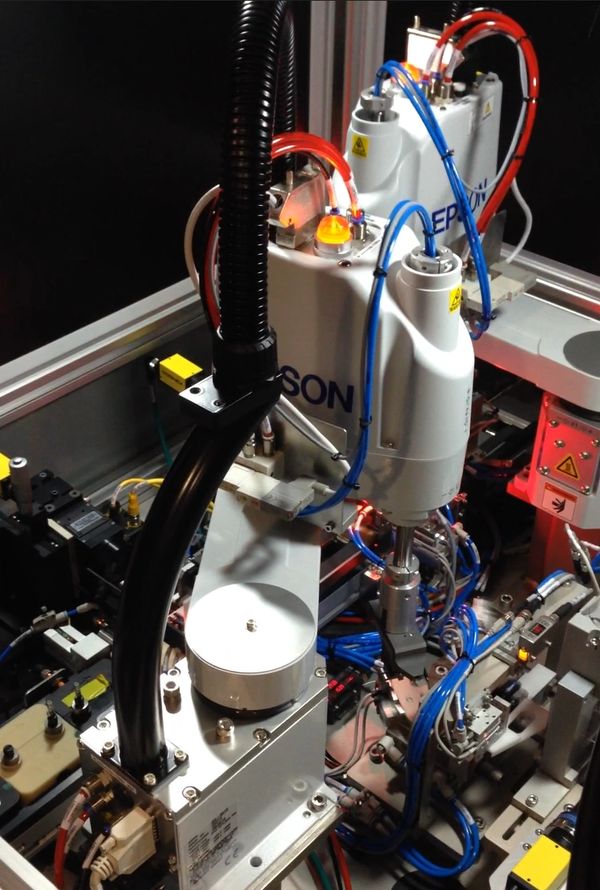

Vape Pen Assembly

Project completed and installed in 180 days. The system features Rockwell PLC controls, RFID tag pallets on a powered and free conveyor, Cognex machine vision, and laser welding. Each of the 9 stations on the line included two Epson Robots.

Shaving Razor Assembly

The continuous motion assembly system developed by Third Coast Automation is capable of running at 600 ppm.